Bearings are designed and manufactured to transmit vertical and horizontal loads from the superstructure to the substructure, while allowing specific movements and rotations of the superstructure caused by wind or seismic effects, temperature variations, deck deflections, elastic shortening due to creep, shrinkage or post-tensioning, etc.

The choice of the type of bearing to be used depends on the type of structures, on the design loads, movements and rotations and can be affected also by the environmental conditions of the project.

The reference European Standard Code is EN 1337.

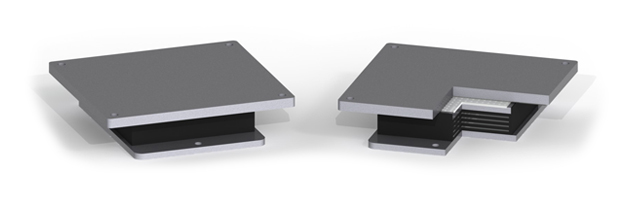

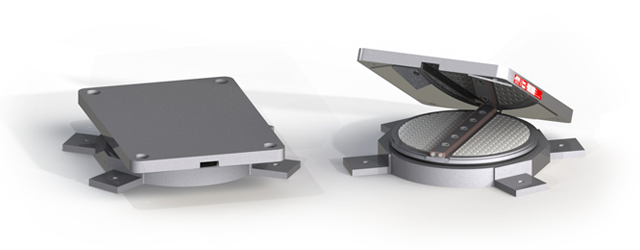

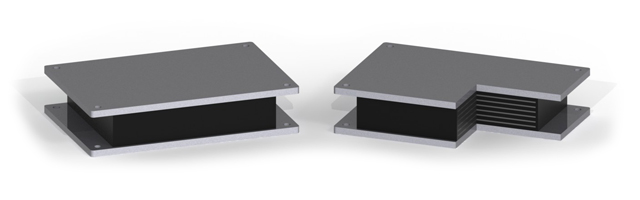

E-Link Elastomeric Bearings

AGOM elastomeric bearings, called E-Link, are built to withstand loads and simultaneous deformation in any direction, while allowing for minor rotations in any of the bearing’s axes. E-Link bearings can be made entirely of rubber (natural or synthetic) or can be reinforced with special sheet steel to increase capacity and transversal strength. Bearings can also be produced with special anchor plates or with sliding surfaces to improve the structure’s displacement capacity. They can be manufactured in rectangular or circular shape according to customer requirements.

This kind of bearing can withstand vertical loads of up to 22000 kN.

The reference European Standard Code is EN 1337-3.

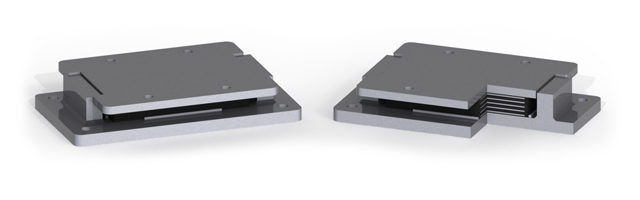

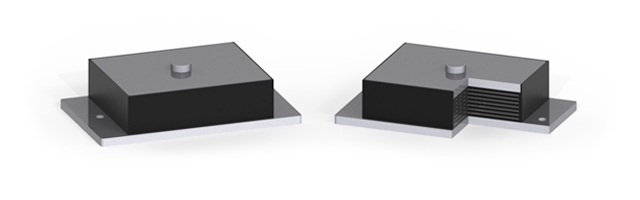

E-Link B

Elastomeric bearings type B have 2 or more reinforcing steel plate to improve their loading capacity. The horizontal loads are transferred from structures to bearings only by friction. It’s the most common type of bearing because it can support heavily vertical loads, allow significant displacements and it’s very easy to install.

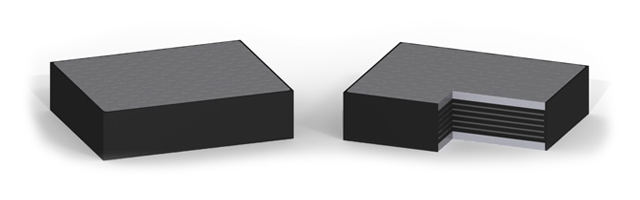

E-Link C2E

Elastomeric bearings type C2E have 1 or more reinforcing steel plate to improve their loading capacity and 2 vulcanised external plates to anchor them, greater than the rubber shape. The horizontal loads are transferred from structures to bearings by means of steel bars or screws bolted to the external plates.

E-Link C4

Elastomeric bearings type C4 have 1 or more reinforcing steel plate to improve their loading capacity and 2 non-projecting vulcanised external plates to anchor them. The horizontal loads are transferred from structures to bearings by means of pins that connect the external plates of the bearings and the counterplates embedded or welded to the structures.

E-Link C4E

Elastomeric bearings type C4E have 1 or more reinforcing steel plate to improve their loading capacity, 1 lower vulcanised plate to anchor them, greater than the rubber shape, and 1 upper non-projecting vulcanised plate to be connected to a counterplate by means of pins or bolts. The horizontal loads are transferred from structures to bearings by means of steel bars or screws bolted to the external plates.

E-Link C5

Elastomeric bearings type C2 have 1 or more reinforcing steel plate to improve their loading capacity and 2 non-projecting vulcanised external plates with checkered surfaces. The horizontal loads are transferred from structures to bearings only by friction, improved thank to the bearing checkered surfaces.

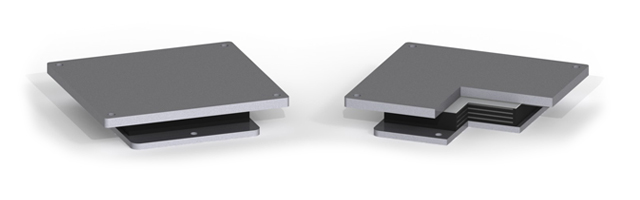

E-Link DP

Elastomeric bearings type DP have 1 or more reinforcing steel plate to improve their loading capacity and their upper surface is made by a PTFE sheet directly vulcanised to rubber, to reduce friction with structure and to allow relative displacements in any direction. On the opposite side, they have a vulcanised plate to anchor them.

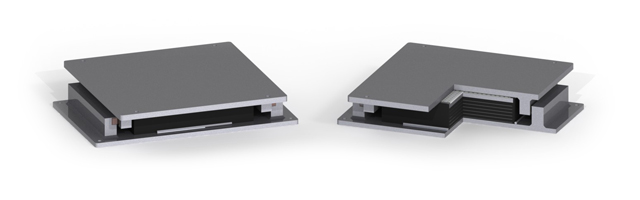

E-Link EG

Elastomeric bearings type E have 1 or more reinforcing steel plate to improve their loading capacity and 1 external vulcanised plate where a PTFE sheet is recessed, to reduce friction with structure and to allow relative displacements. They have 2 external guides to prevent movement in the transversal direction and allow displacements only along the longitudinal direction.

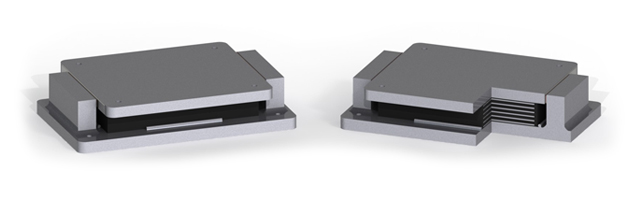

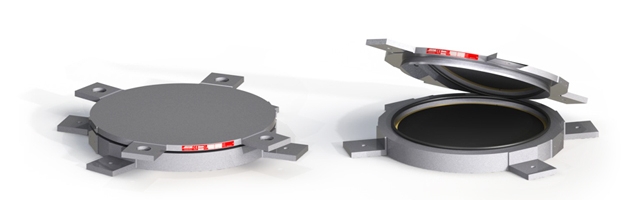

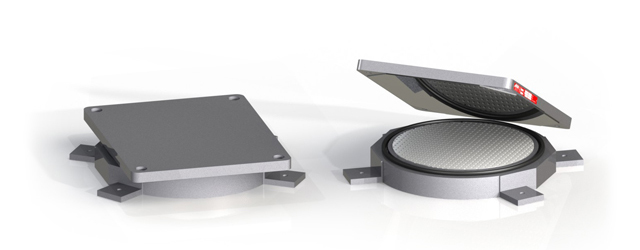

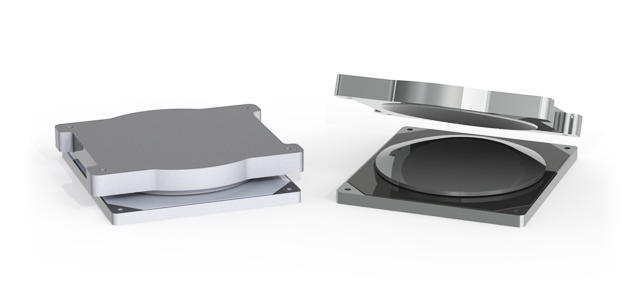

V-Max Pot Bearings

AGOM pot bearings, called V-Max, are built to withstand big loads and simultaneous large deformation in any direction, while allowing for minor rotations (<0.03 rad) in any of the bearing’s axes. A completely encased rubber pad is positioned in a steel pot; under high pressure the pad behaves like a liquid; elasticity of rubber allows tilting movement (rotation) of the piston in the horizontal axis. Movement capacity is obtained by coupling a sheet of a low friction material (for example PTFE) with a stainless steel surface. Depending on the configuration, they can accommodate horizontal loads as well as movements in longitudinal or/and transversal directions.

This kind of bearing can withstand vertical loads of up to 100.000 kN.

The reference European Standard Code is EN 1337-5.

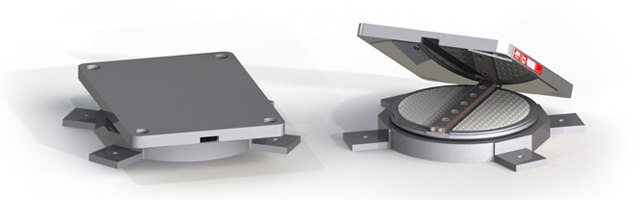

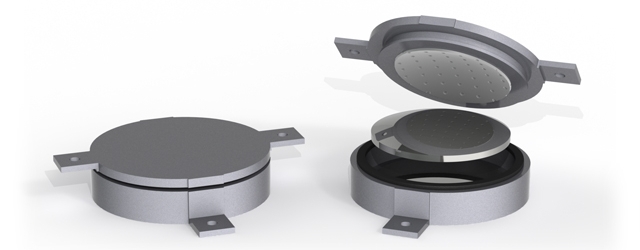

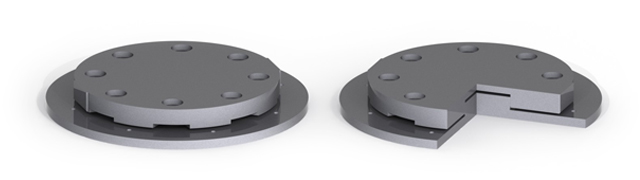

R-Max Spherical Bearings

AGOM spherical bearings, called R-Max, are built to withstand big loads and simultaneous large deformation in any direction, while allowing for large rotations (>0.02 rad) in any of the bearing’s axes. Rotation capacity is obtained by coupling an internal median plate machined as a spherical surface and a complementary plate where a sheet of a low friction material (for example PTFE) is recessed. Movement capacity is obtained by coupling a sheet of a low friction material (for example PTFE) with a stainless steel surface. Depending on the configuration, they can accommodate horizontal loads as well as movements in longitudinal or/and transversal directions.

This kind of bearing can withstand vertical loads of up to 100.000 kN.

The reference European Standard Code is EN 1337-7.

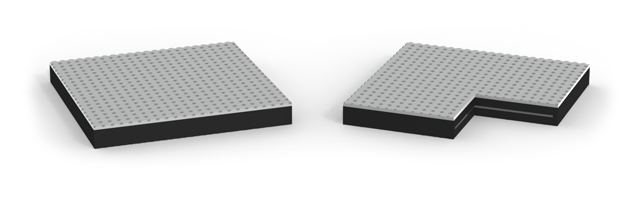

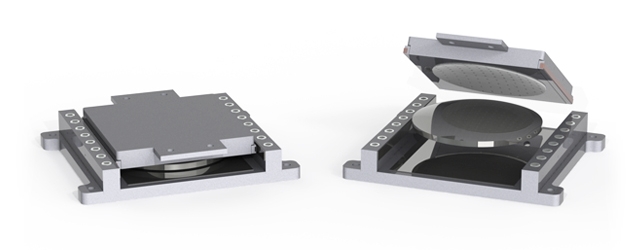

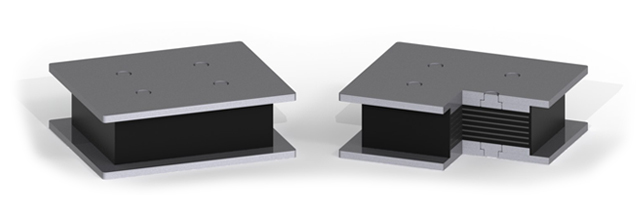

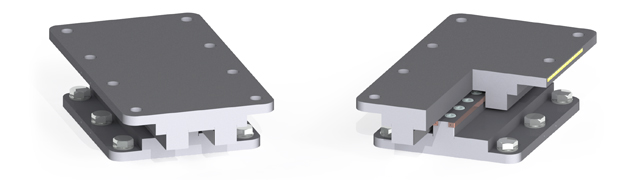

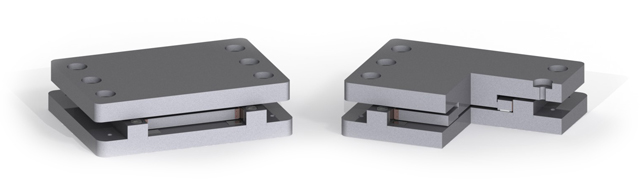

H-Max – Horizontal Load Bearings

AGOM horizontal load bearings, called H-Max, are built to withstand horizontal loads and simultaneous large deformation in any direction, while allowing for rotations in any of the bearing’s axes. They are made of steel, while the movement surfaces are obtained by coupling a sheet of a low friction material (for example PTFE) with a stainless steel mirror polished surface.

The reference European Standard Code is EN 1337-8.

HLBG

Horizontal load bearings type HLBG (guided) enable rotation around the transversal axis and movement only along the longitudinal axis, while can transfer horizontal load in the transversal direction. They can be connected to the structured by means of anchor bars or bolts.

HLBG-R

Horizontal load bearings type HLBG-R (guided with rotations) enable rotation in any direction and movement only along one direction, while can transfer horizontal load in the transversal direction. They can be connected to the structured by means of anchor bars or bolts.